Expanded Metal Terminology #1

How to measure expanded metal

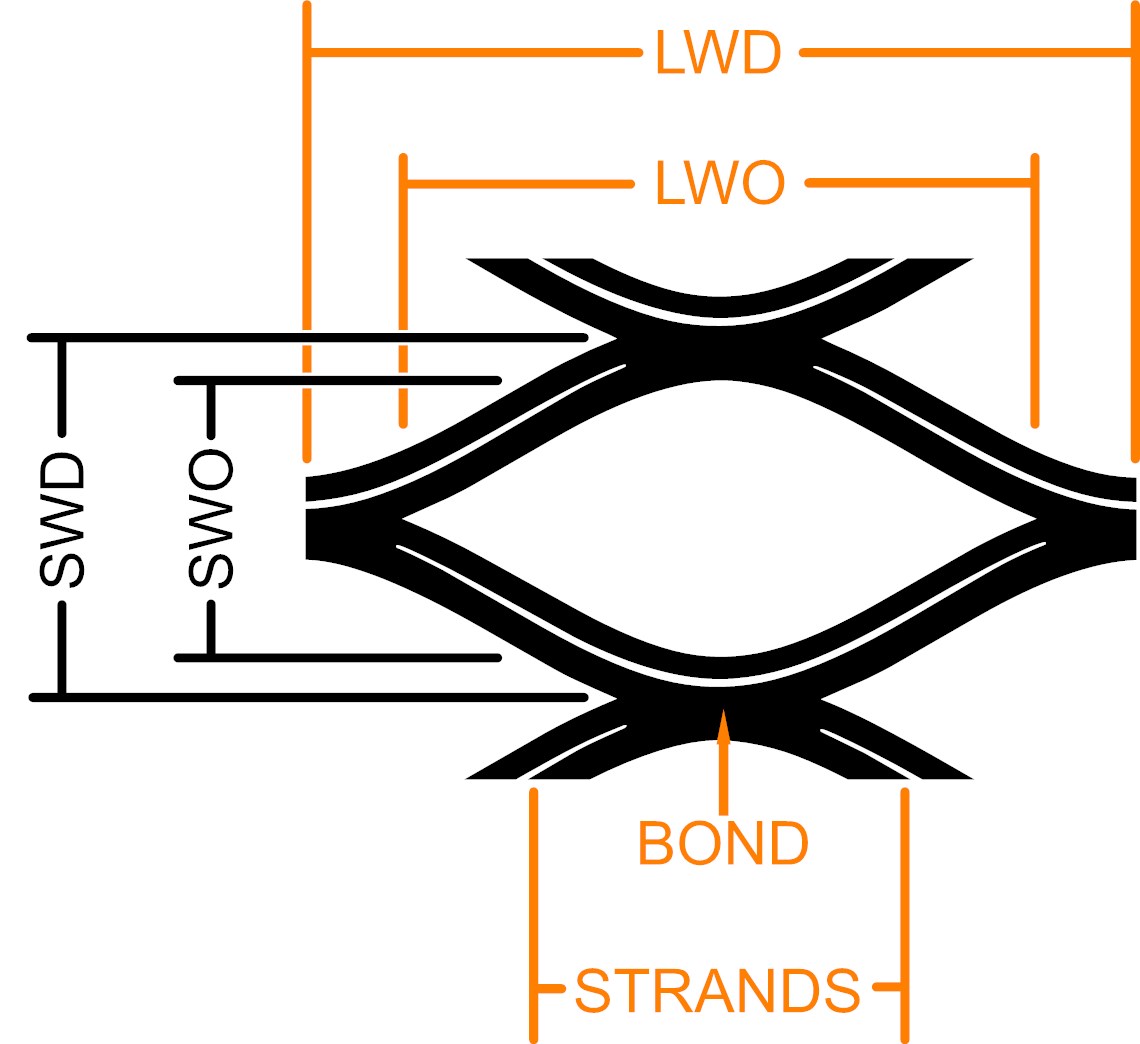

LWD = Long Way of Diamond

The length of long diamond diagonal from one pitch point center to another pitch point center.

LWO = Long Way of Opening

The length of long diamond diagonal.

SWD = Short Way of Diamond

The length of short diamond diagonal from one pitch point center to another pitch point center.

SWO = Short Way of Opening

The length of short diamond diagonal.

Bond

The solid intersection of two strands

Strands

The sides of expanded metal design.

Expanded Metal Terminology #2

Understanding the cutting process

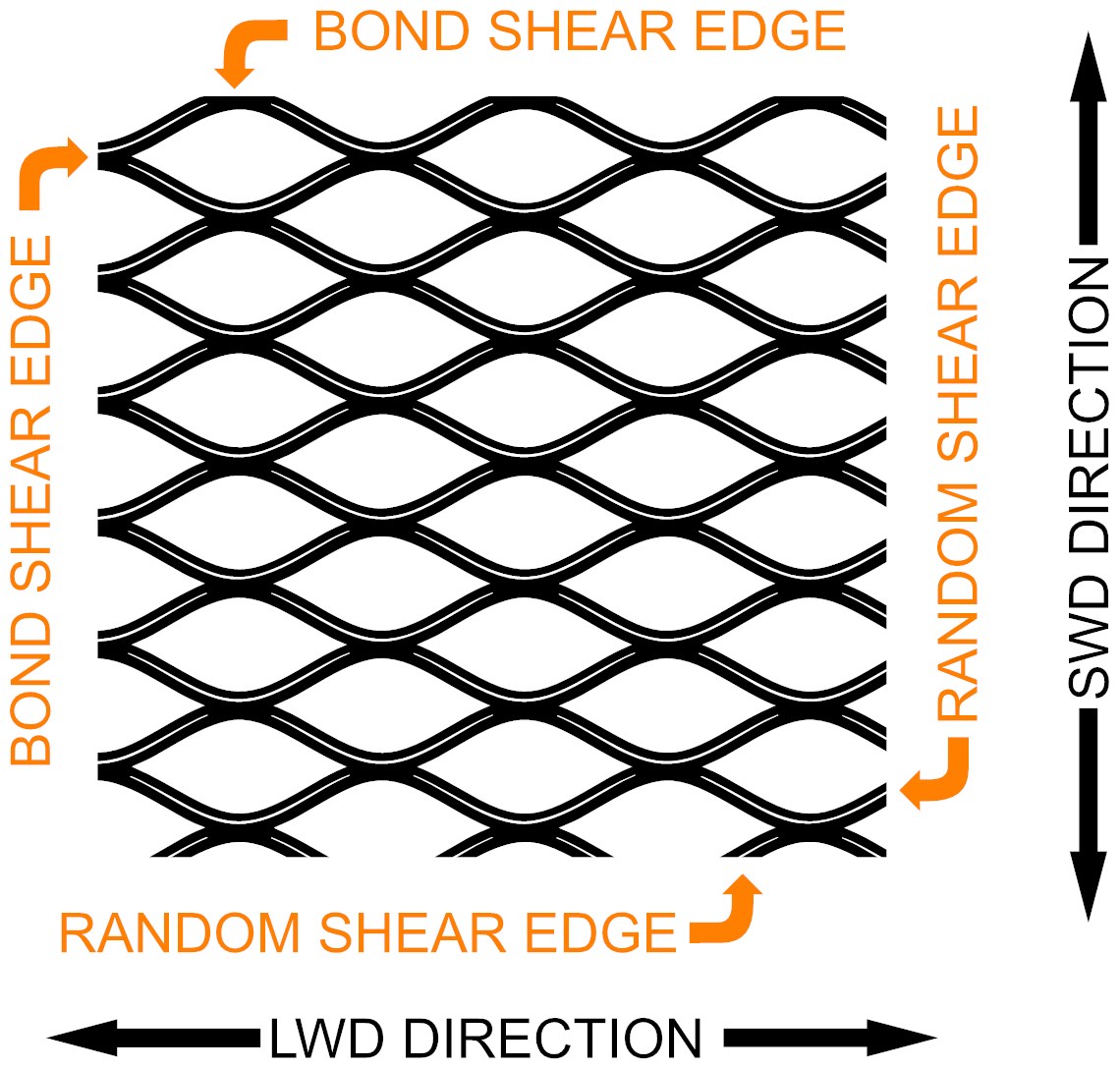

Bond Shearing

Results in closed diamond design and angle, eliminating jagged edges and prongs. Shearing cuts through expanded metal at center of bond, where strands intersect. Bonded parts are a superior product to random sheared parts but do require greater dimensional tolerance.

Random Shearing

Results in open diamond design and angle, leaving jagged edges and prongs in most cases. This option is most often chosen when tight dimensional tolerances are critical, and sharp edges don't pose a problem.

Expanded Metal Terminology #2

Thinking about thicknesses

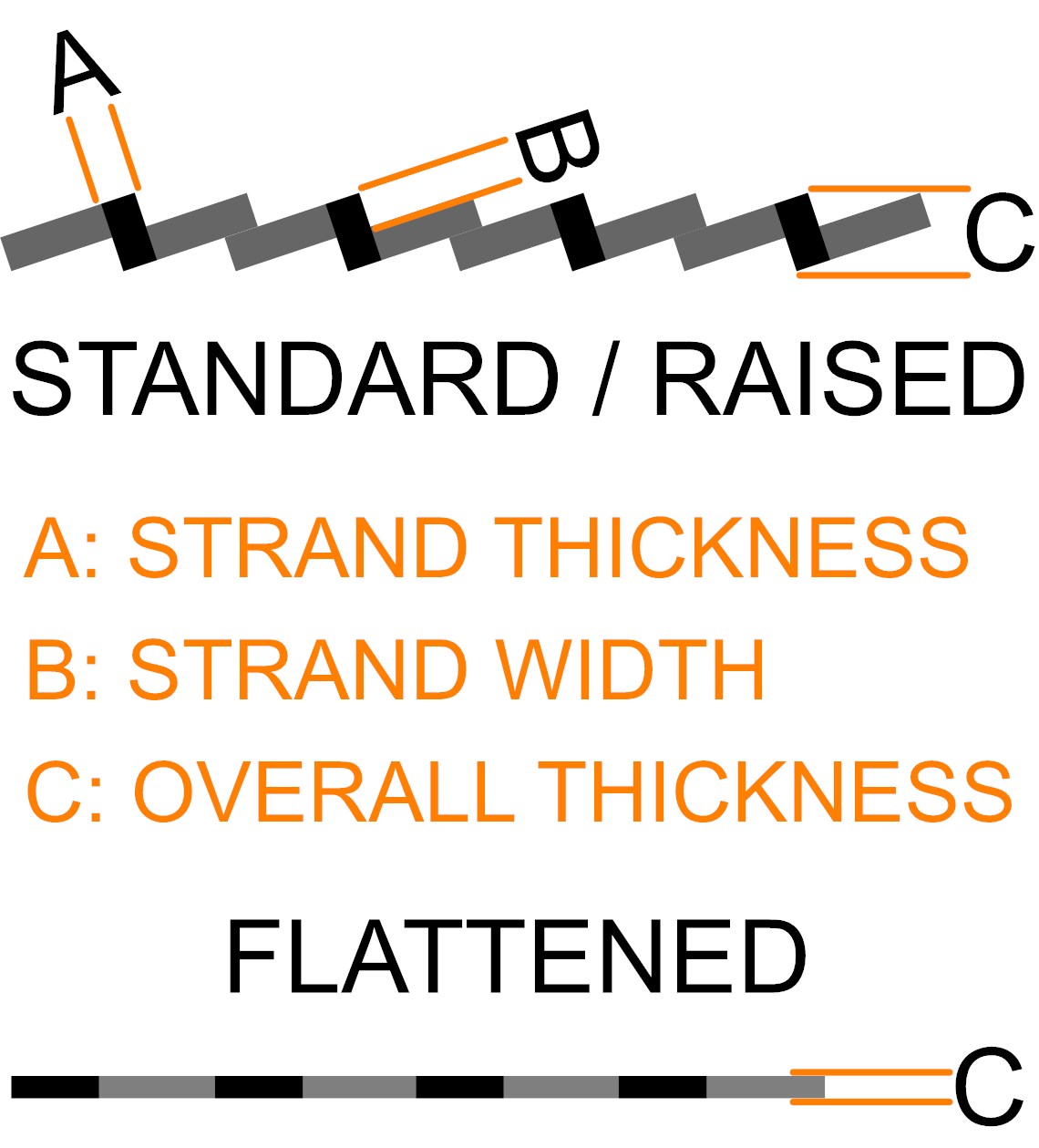

Standard Expanded Metal

The strands of standard expanded metal are angled—rather than fixed—on a horizontal plane, which makes the material less smooth than its flattened counterpart.

The particular characteristics exhibited by a sheet of standard expanded metal are largely determined by the amount of expansion applied, the pattern size, and base sheet thickness. However, in general, the uneven surface offers enhanced structural strength and better gripping properties. Depending on the pattern design, the material can also be used to direct the flow of light, air, fluids, and solid materials.

Flattened Expanded Metal

Compared to standard expanded metal, flattened expanded metal is thinner, flatter, and wider/longer, which translates to approximately 5% lower material weight. This characteristic, combined with the finished surface, makes it suitable for applications where a lower risk of abrasion and an aesthetic appearance are critical.